Contact Information

AftercoolerSales.Com

Festus, Missouri 63028

503-653-5571

sales@aftercoolersales.com

Click Here To Email Us

.

.

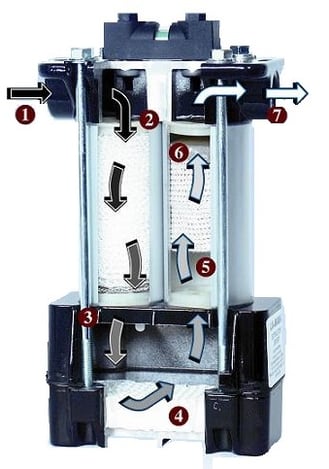

The patented Extractor/Dryer® is a two-stage, point-of-use compressed air filter. Designed primarily for the final usage of air, it will remove water, oil and other contaminates from compressed air lines. The Extractor/Dryer was developed for air driven tools, paint spraying, manufacturing equipment or any other compressed air equipment to produce clean, dry compressed air. In return you receive extended equipment life, improved product quality, reduced downtime, and savings on costly repairs to damaged equipment. These advantages will pay for themselves in a short amount of time.

La-Man Standard Features include:

EXTRACTOR/DRYER – HOW IT WORKS:

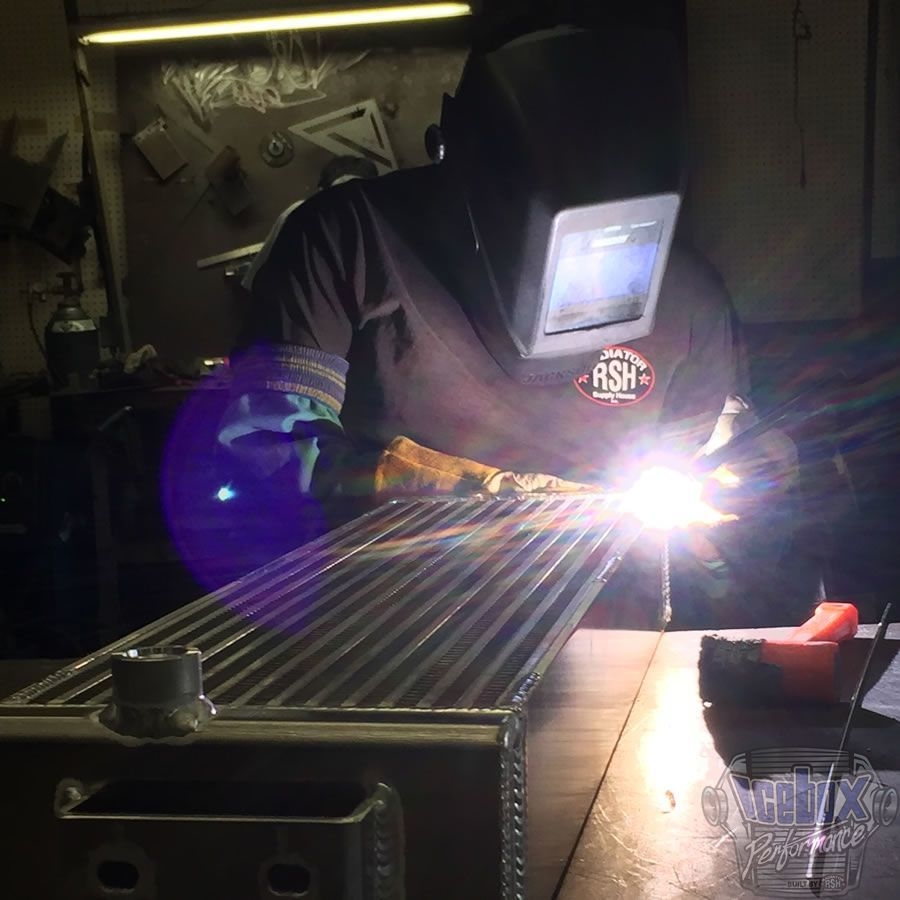

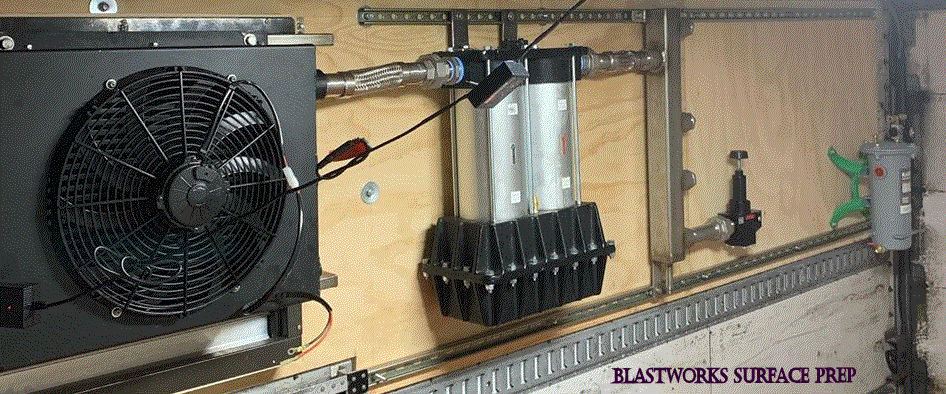

Blasting and painting professionals know that dry compressed air is crucial to successful surface preparation. Flash rusting, clogged blast pots, corroded valves, wasted media and paint fisheyes are common problems caused by wet, oily air and can be prevented. AftercoolerSales.Com aftercoolers and coalescers work as a team to provide an economical moisture removal solution and allow you to get the job done right with properly conditioned, clean, dry compressed air.

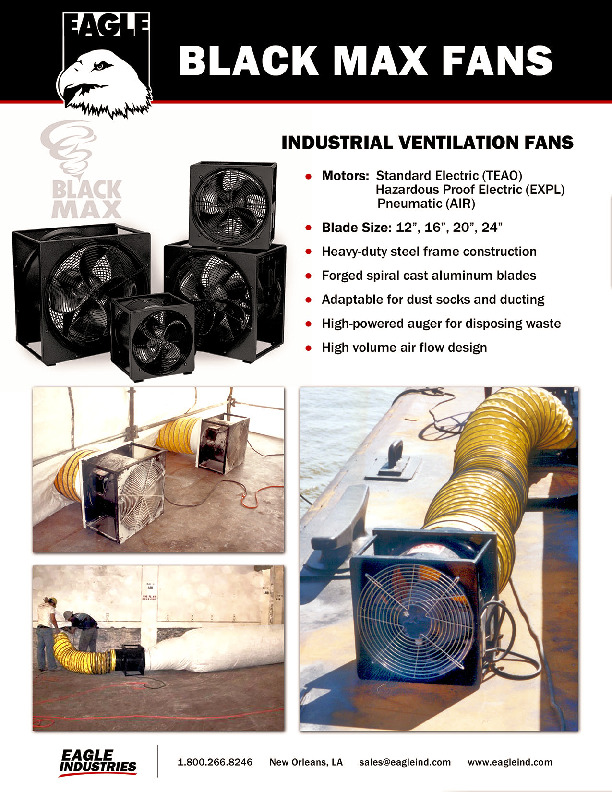

AftercoolerSales.Com, LLC features the Best of the Best in sandblasting and painting support equipment. Aftercoolers, Coalescing oil/water/particle removal, High volume fans, air movers and dust socks. Grade D breathing air and respirators. Pneumatic motor waterproof LED magnetic lights. We will help you make sense of it all.

John was a professional repair technician in electronics and automated commercial/industrial equipment prior to opening his first business at age 25. He sold, installed and repaired large automotive equipment for a number of years which led to soda blasting. He currently has over 30 years experience in the soda blasting, cob blasting and sandblasting world. His company, Eco-Blast.Com, LLC began manufacturing soda/cob blasting pots 17 years ago and introduced the first All-Media Soda Blast Pot. A sister company, Soda-Blast.Com was his on-site and in-house blast booth labor arm providing service to residential, commercial and industrial customers. He knows blasting and he knows equipment. He can help you choose and design systems to meet your needs.