Moisture Removal

La-Man’s Extractor/Dryer®

The patented Extractor/Dryer® is a two-stage, point-of-use compressed air filter. Designed primarily for the final usage of air, it will remove water, oil and other contaminates from compressed air lines. The Extractor/Dryer was developed for air driven tools, paint spraying, manufacturing equipment or any other compressed air equipment to produce clean, dry compressed air. In return you receive extended equipment life, improved product quality, reduced downtime, and savings on costly repairs to damaged equipment. These advantages will pay for themselves in a short amount of time.

Moist Soda in the media valve

Moisture in the electrical solenoid

Moist Soda in the tank

Moisture in the tank. Soda (white) has clumped and not flowing

La-Man Standard Features include:

- Differential Pressure Gauge (All models except 520’s and 195A) – Allows the user to visually see the change from green to red, indicating a pressure drop of 10 PSI or greater you will need to service the elements. Service Kits available for all models

- Weep Drain – Allows minimal, continuous flow of contaminated air to escape the base of the unit.

- Mounting Brackets (All models except 520’s and 195A) – Allows for easy and protective mounting of your Extractor/Dryer.

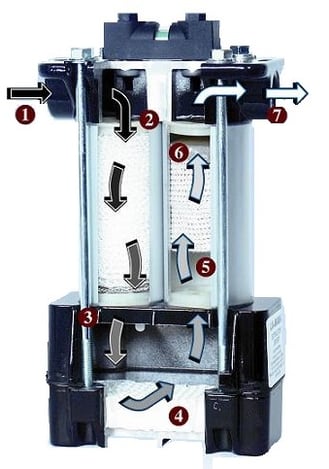

EXTRACTOR/DRYER – HOW IT WORKS:

- (1) Compressed air containing tiny particles of dirt, dust, oil, rust and moisture enters the first stage of the La-Man® Extractor/Dryer Filter.

- (2) A coalescing effect occurs as air passes through a cartridge mesh filter, which captures larger particles and causes moisture to form larger droplets.

- (3) Air velocity lessens as it enters the extraction chamber allowing particles to collect and moisture to condense on the honeycomb.

- (4) Particle-laden liquid flows along the bottom and out the drain.

- (5) Air passes through the second stage wire supported fiber filter cartridge, which captures remaining particles down to 5 microns (smaller microns down to 0.01 are available).

- (6) Remaining moisture and contaminants are dried and filtered in the second stage filter.

- RESULT: Exhaust air is clean and dry – no dirt, rust, oil, or moisture or disrupt air equipment operation.

Ask Us About Them Here